Cleansing power improvement (reduction of cleaning cost and improvement of yield rate)

Effects in laundry business

Effects by The Biowater

- Good cleansing power – white materials washed up whiter

- No alkari burn – No yellowing with detergent residues

- Good finish – Wrinkles after drying are reduced with wool items.

- More soluble with detergent and starch

- Amount of detergent is reduced

- Water consumption for rinsing is reduced

- Fuel consumption of the boiler is reduced by approx. 10%

Cleansing power of pure water is increased, and deterioration speed of solvent is reduced to 1/2

Building: electronics manufacturing plant Location: Odawara city, Kanagawa prefecture

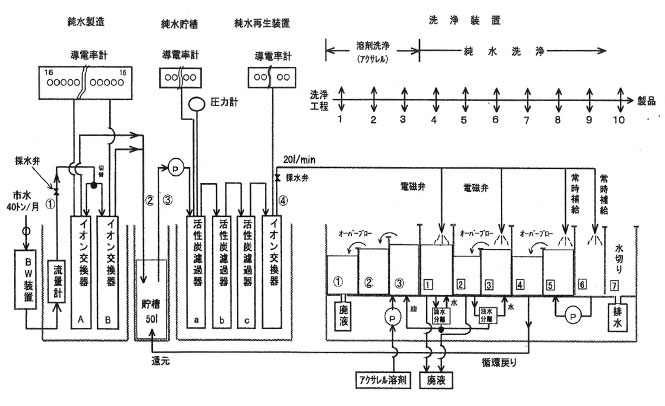

Outline block diagram of pure water cleaning system at PCB (package board)

Manufacturing plant. (Odawara Custom Manufacturing Service Co., Ltd.)

Evaluation report of Installation of BW water reforming device

at pure water cleaning system in Package Board manufacturing line at Odawara CMS Co., Ltd.

Evaluation carried out by Mr. Hiroyasu Nakajima, certified environmental measurer, Odawara CMS Co., Ltd.

| Test purpose | evaluation item | evaluation method | Test result | Judgement |

| Cost reduction of consumables | Lengthen life of ion exchange resin | Montoring Electric conductivity of Pure water (electric conductivity meter) | Under evaluation (electric conductivity seems stabilized) | |

| Lengthen life of solvent cleaner | Monitoring Flux density (Liquid chromatography) | Deterioration speed of solvent cleaner is reduced to less than 1/2 | Excellent | |

| Improvement of cleansing power | Improvement of cleansing power of the product | Product surface observation (SEM, FT-IR) | Under evaluation (product inspection such as visual inspection is OK) | |

| Improvement of cleansing power of pure cleansing fluid | Analysis of solvent (oil and water separation liquid) at pure water cleaning layer (Fluorecent X ray, SEM, EDX) | Confirmed improvement, as lots of metal substances (Cu,Pb,Fe,Cr etc.) and soldering balls are detected in the solvent | Excellent | |

| Cleaning of cleansing layer | Analysis of deposit in filter tank of pure water cleaning layer (SEM, EDX) | There were less deposits in filter tank. We found no deposition of needle crystals of silika and calcium which were found in the similar facility without BW device installation. | Good |

Pure water cleaning system for Printed Circuit Board (Package Board) at Odawara Custom Manufacturing Service Co., Ltd.

Package Board (Printed Circuit Board) is a heart of microcomputer. Since any dirt of micron order is not allowed at production site, and the product is washed with pure water and solvent repeatedly.

After BW water reforming device was installed, metal debris of micron order can be eliminated which was not possible in the past.

And, product yield rate was increased. Furthermore, deterioration speed of solvent became 1/2, and big cost reduction was realized.

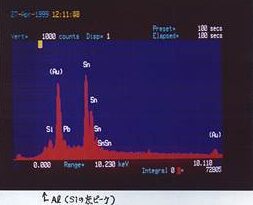

Before installation of BW

Peaks of Au (gold) and Su(tin) are shown. (Gold and tin are washed away by detergent.)

After installation of BW

Peaks of Au(gold) and Sn(tin) became even higher, and peaks of Al(aluminum) and Pb(lead) are shown though they didn’t before installation of BW. Also, peaks of Cu(copper) and Cr(chromium) are shown. It shows that cleansing power is increased.

From the data analysis, following three points are confirmed in two weeks after installation of BW water reforming device.

1. Lengthening of solvent cleaner life

Deterioration speed is reduced be less than half.

2. Cleansing power of pure water cleaning liquid is increased

Lots of metal composition (Cu,Pb,Fe,Cr etc.) and solder balls are washed away, and increase of cleansing power is confirmed.

3. Purification of filtering tanks

Deposit in filtering tanks are less, and no deposition of calcium scale.

Realized 100% yield rate with improved cleansing power (a case at a copy machine manufacturer)

Quality of copying machine depends on perfection of true circle of the heat roll with which ink is pressure-bonded on papers. Therefore, lots of manufacturing technique are used for development of making perfect circle of the heat roll and improvement of yield rate of finished products.

Washing away all impurities produced during production is the key to create perfect circle. At this plant, they tried to improve cleansing liquid many times, but yield rate reached the ceiling at 90%.

Then, in the process of polishing→hot water cleaning→drying→ferri-coating (zinc phosphate film treatment)→surface roughness inspection, BW water reforming device was installed in the cleaning machine and water was reformed. The result was that yield rate at the heat roll became 100%, and big cost reduction was realized with elimination of inspections at some points, etc.