Overcome red rust corrosion with black rust!

“Magnetite Rust Method®” (Oxide Coating Film Method) for water pipes is a method for lengthening the life of water supply pipes by changing red rust in water pipes into black rust (i.e. magnetite) by installing BW water reforming device (The Biowater®) in water pipes and water tanks, and running reformed water in the pipes.

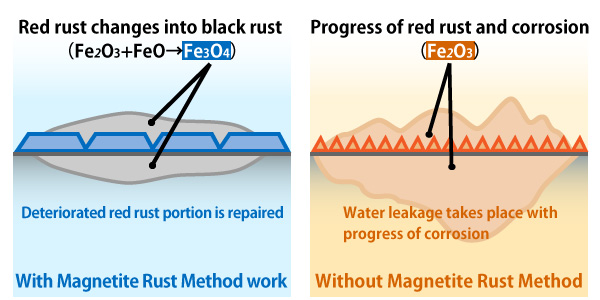

Black rust is formed like a coating filling between base metal and rust layer, and base metal is protected by crystalline black rust. Since black rust is 10 times more dense than red rust, and is stable, it improves pipe clogging and red water (rust water) problems. Pipe clogging risk can be avoided because the old water pipes which are about to cause water leakage will be repaired by black rust. When black rust is formed inside the water pipes, it will fill up reduced corroded wall and pipes recover original thickness like new pipes. For the water pipes already having water leakage, corroded and thinner part of wall of the pipes will be repaired gradually and water leakage will soon stop.

※We changed the name of the method from previous “Oxide Coating Film Method” to “Magnetite Rust Method for water pipes”.

How “Magnetite Rust Method” for water supply pipes is created.

Prior art of Magnetite Rust Method is the highly weather resistance steel, Trade Mark “Cor-Ten steel” which is known as the best anti-corrosion steel. It controls rust by using rust. Using this concept, we developed our technology for rust prevention method for water supply pipes.

While paint to make coating film over the steel is applied in the case of Cor-Ten steel, “Magnetite Rust Method” works on the water running through the pipes. It is industrialization of Japanese traditional technology of water reformation, and we completed as anti-corrosion method.

Effects of Magnetite Rust Method

Water leakage prevention

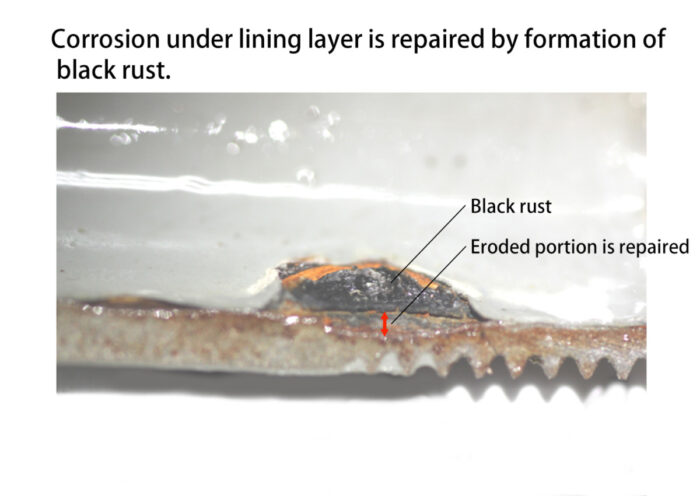

This is an example of an old water pipe that was about to cause water leakage was repaired and water leakage could be avoided by formation of black rust in the pipe.

Following photos were taken when Magnetite Rust Method was applied for the water pipes which were 21 years old, and photos show the shots 5 years after the work.

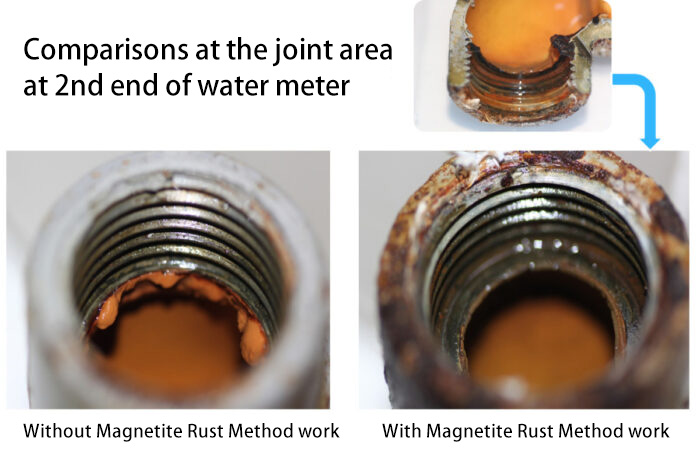

We can observe the following facts from the enlarged photos of the screw threads at the joint area.

- Water invaded between base metal and lining layer at the edge of male screw threads at the joint area. And, deterioration under lining layer progressed by red rust for 20 years.

- There is a trace of base metal being eroded by 2/3, but now black rust layer is formed.

- Now there is no sign of base metal being eroded from formation of red rust.

- Thickness of the base metal in pipe wall which was deteriorated with red rust, is now recovered with formation of black rust.

2 and 3 of above items happened in five years after installation work of Magnetite Rust Method, and aging deterioration of water supply pipes stopped. And, it can be confirmed that original pipe wall thickness is recovered with formation of magnetite (black rust).

Example at the office building of a railway yard

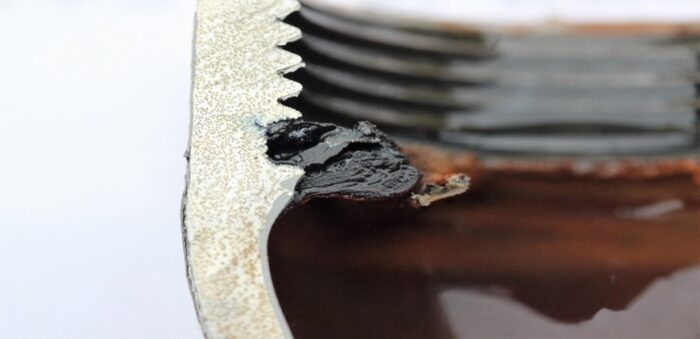

Work was done in December 2006, and investigation was done ten years later

Black rust is fully formed to the area of screw threads of joint area where water is running and corrosion takes place.

(Cross section view) Two screw threads of black rust layer is formed around inside wall of the pipes, and base metal corrosion is inhibited.

Red rust layer is adhered to calcium film on the surface of corrosion layer. Black rust is formed inside of red rust layer.

Also, during the process of red rust becoming to black rust, red rust volume is reduced and interstice of impurity layer surrounded by red rust is found.

Stable effects for a long period

Test for long lasting effects(23 years after the work)

- Place: Kasama, Sakae-ku, Yokohama city

- Building: built in April 1989

- BW installed: April 1992

- Investigation: May 2015

Test organization: Yokohama City Center for Industrial Technology and Design(H27-000)

Black rust is formed for two screw threads contacting with water. Black rust layer which is formed around the male screw threads in the pipe edge, looks like sticking out screws.

Countermeasure for red water

We don’t experience “red water” in tap water pipes today, but there are lots of red water problems for circular water pipes in factories. When we see red water, it is a sign that deterioration of water supply pipes is progressing, and soonest countermeasure should be taken since water leakage will happen sooner or later.

Improvement for clogging in water pipes (water supply pipes within the building)

As deterioration of water pipes progress, inside diameter of the pipes will be reduced with adhesives such as red rust. The clogging will cause short supply of water and defective ignition of gas appliances will happen and there will be problems with production equipment in the factories.

Cause of pipe clogging comes from the fact that red rust has many interstices and gathers various impurities in the water with calcium compound, and its volume becomes big.

By applying Magnetite Rust Method, red rust becomes black rust. Then, volume of rust becomes 1/10 and contained impurities are discharged. Therefore, not only red rust but also carbonated calcium compound are washed away after Magnetite Rust Method is applied. To avoid discharging of red rust, cleaning of water pipes will be done before applying Magnetite Rust Method.

We do cleaning of water pipes by JAB (Jet Air Bubble) cleaning method(compressed air method), H2O2 cleaning method, etc. according to the conditions of old pipes.

Application example of pipe clogging improvement(9 months after Magnetite Rust Method work)

Clogging rate is improved by 70% in 9 months after the work.

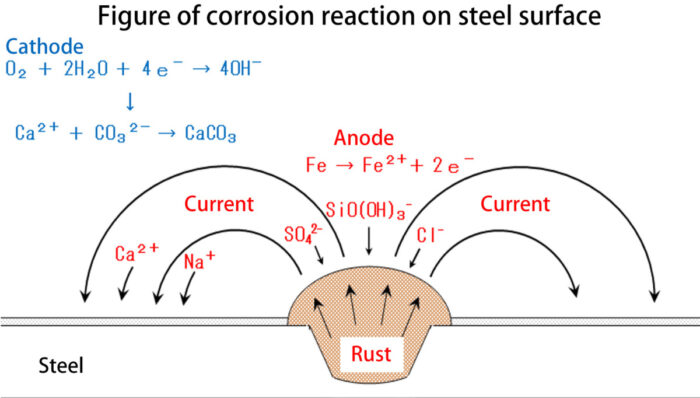

Mechanism of Black Rust formation

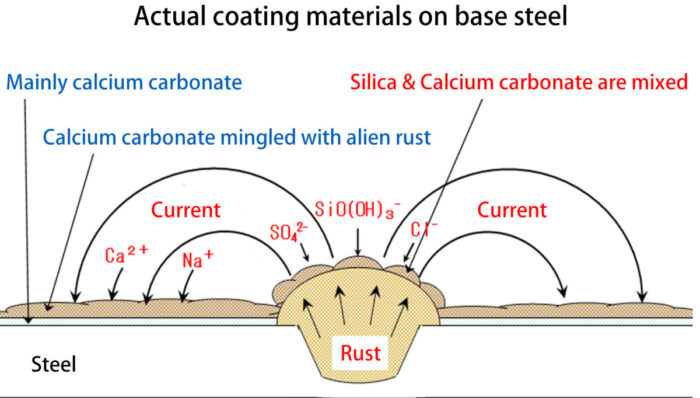

Figure of corrosion reaction and actual coating material on base metal

Densification of calcium carbonate film

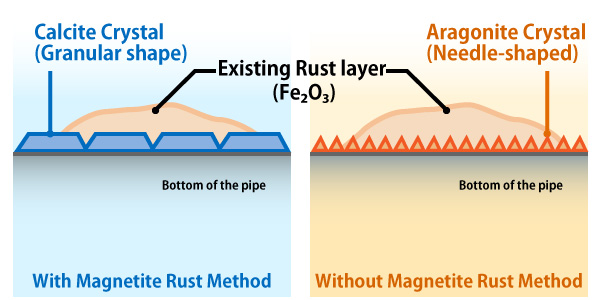

In regular tap water in city area, Aragonite Crystal is formed on the surface of water pipes due to chlorine in tap water. In reformed water with Magnetite Rust Method, Calcite Crystal is formed.

Calcium Carbonate film (200x by microscope)

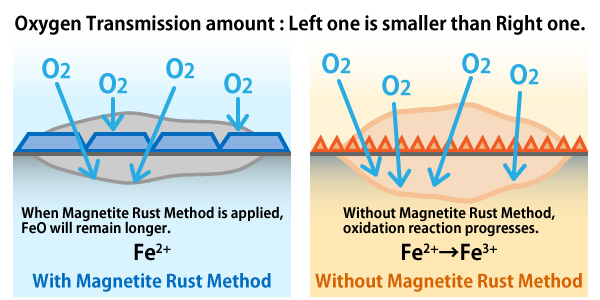

Oxygen supply is reduced under Calcium Carbonate film

Oxygen supply (dissolved oxygen in water) to the iron (base steel of water pipe) is reduced with formation of dense Calcium Carbonate film, and FeO remains longer. At the same time, corrosion current is reduced and oxidation reaction is suppressed.

Red rust on base steel changes into black rust

Red rust (Fe₂O₃)and Iron oxide (FeO)are united and black rust (Fe₃O₄)is formed.

FeO which remained because oxidation reaction was inhibited, and it is combined with red rust, and then red rust becomes black rust.

Scientific proof of the effects

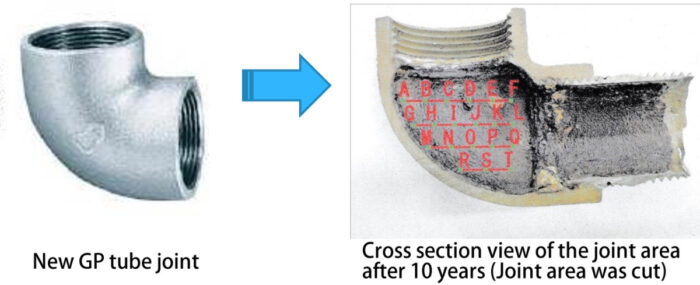

Magnetite Rust Method was applied for a new water pipe, and joint area of the steel pipe is checked after 10 years.

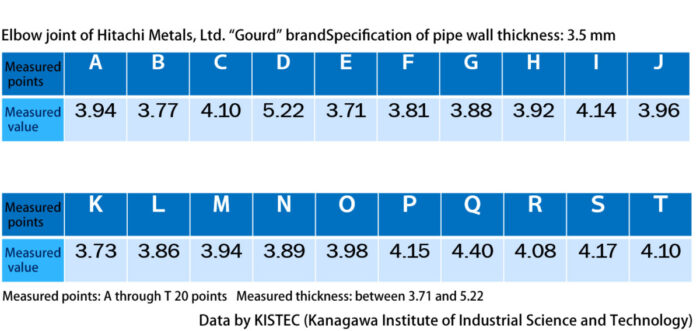

Measurement data of pipe wall thickness for GP tube joint after 10 years

Any point from A to T (20 points) had thicker wall thickness than that of new product.

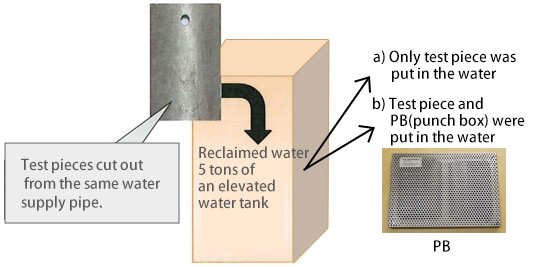

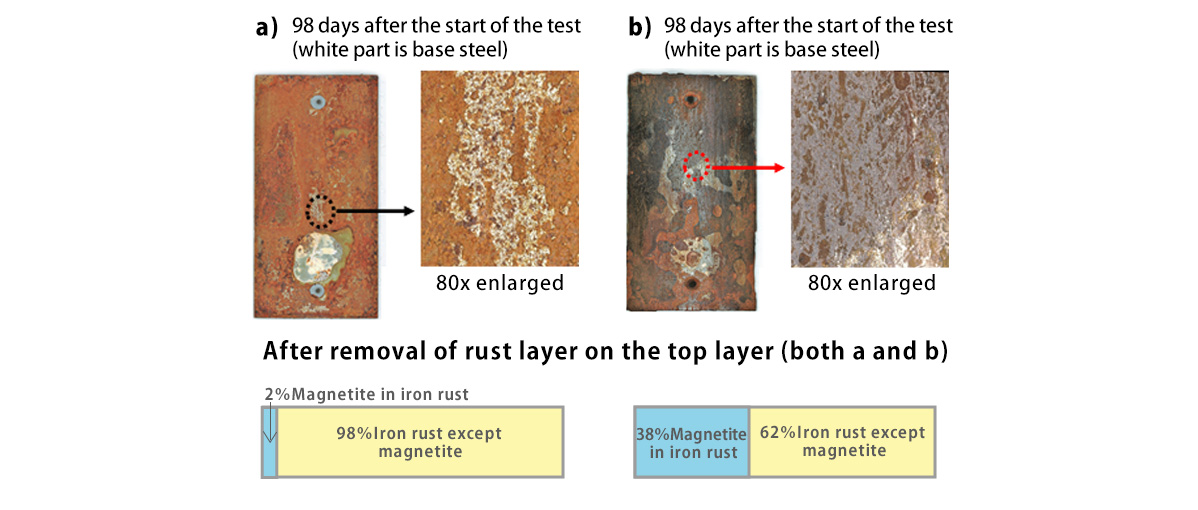

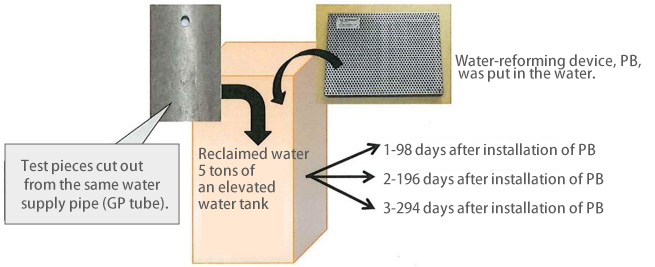

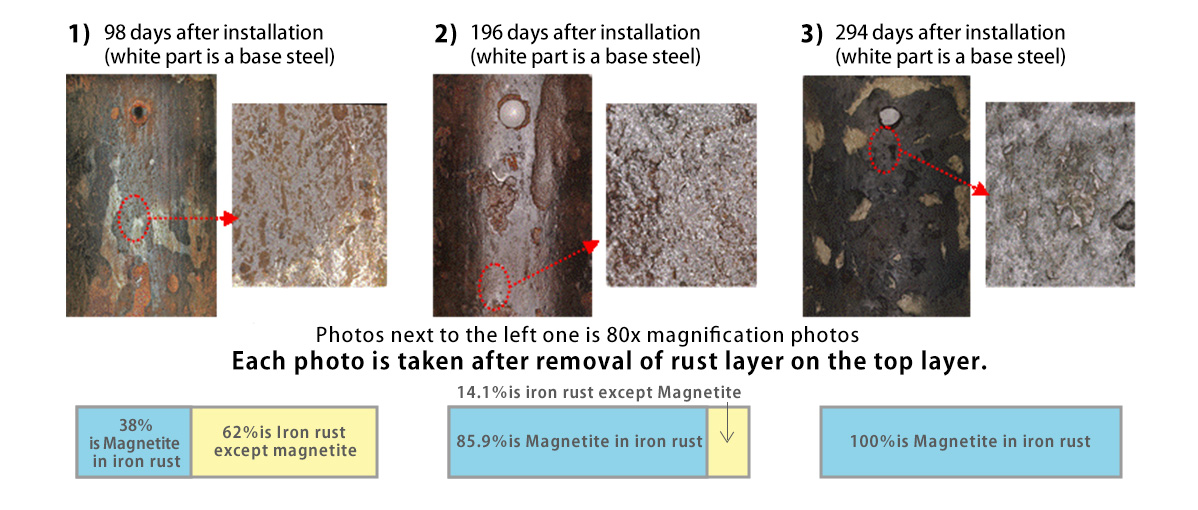

Change from red rust to black rust – progress observation data

Progress observation data for the change from red rust to black rust and the increase of magnetite(black rust) was published at the technology assembly.

(At the 40th Rust and Corrosion Prevention technology assembly, July 2020.) (Excerpt from the case of Shinjuku Mitsui Building)

Comparison test of the test pieces before and after the Magnetite Rust Method work

Click here for inquiries, questions and estimate quotations

The progress of changing from red rust to black rust (magnetite) can beConfirmed. In about 300 days from PB installation, red rust is completely changed into black rust.

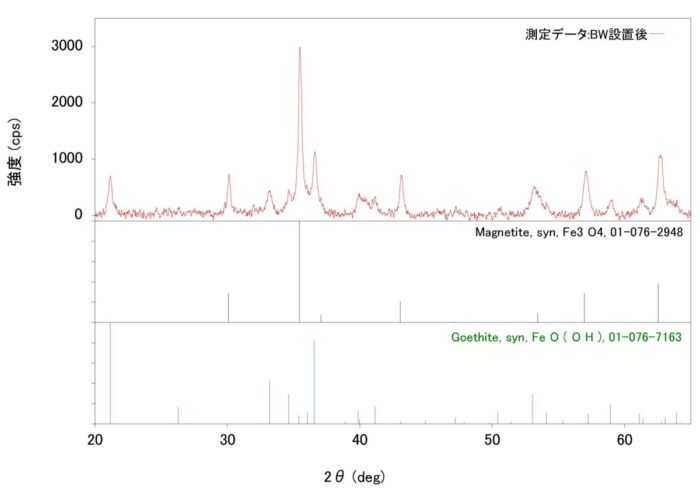

Material analysis by X ray diffraction

All analysis of rust elements as shown is carried out by public authorized test agency.

Component identification and calculation of component ratio are done using X ray diffraction test equipment.

Measuring equipment to judge possibilities of forming black rust (magnetite)

The effects by BW water reforming device can’t be clearly evaluated by conventional water analysis. We established how to evaluate the effects by BW water reforming device by focusing on character changes of a substance.

BW water reforming device (Registered trademark “The Biowater”) is created by the technology to reform water using crystals of natural minerals.

To establish this device as an industrial technology, following three factors must be met:

(1)“Reproducibility” (2) “Rationality” and (3) “Operability”

“Reproducibility” was realized by making certain recipe to blend and prepare artificial crystals of minerals instead of crystals of natural minerals of traditional technology.

And, “Rationality” was realized by finding out the process of red rust changing into black rust.

“Operability” was realized by developing measuring equipment which can measure the degree of water reformation. Thus, Magnetite Rust Method was completed as industrial technology, and it was certified under NETIS ( evaluation technology for old buildings and facilities under New Technology Information System of Ministry of Land, Infrastructure, Transportation and Tourism).

Process of Magnetite Rust Method for water pipes

STEP1Hearing survey of the current degradation status

STEP2Water quality test by our proprietary method (not free-of- charge)

STEP3Investigation by removing pipes(not free-of-charge)

※Click here for details of degradation diagnosis and water quality test≫

STEP4Price quotation and decision of repair service method by selection of construction methods

STEP5Installation of BW water reformation device

※STEP2 and STEP3 can be eliminated.。

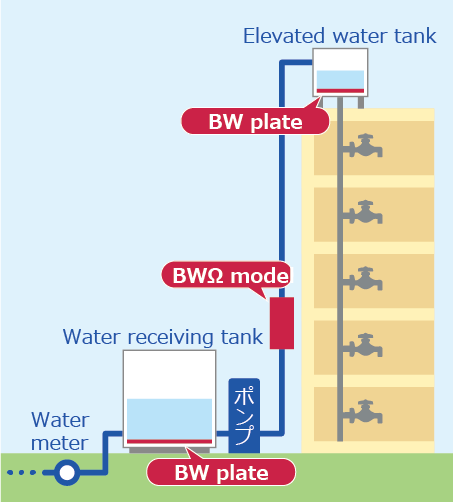

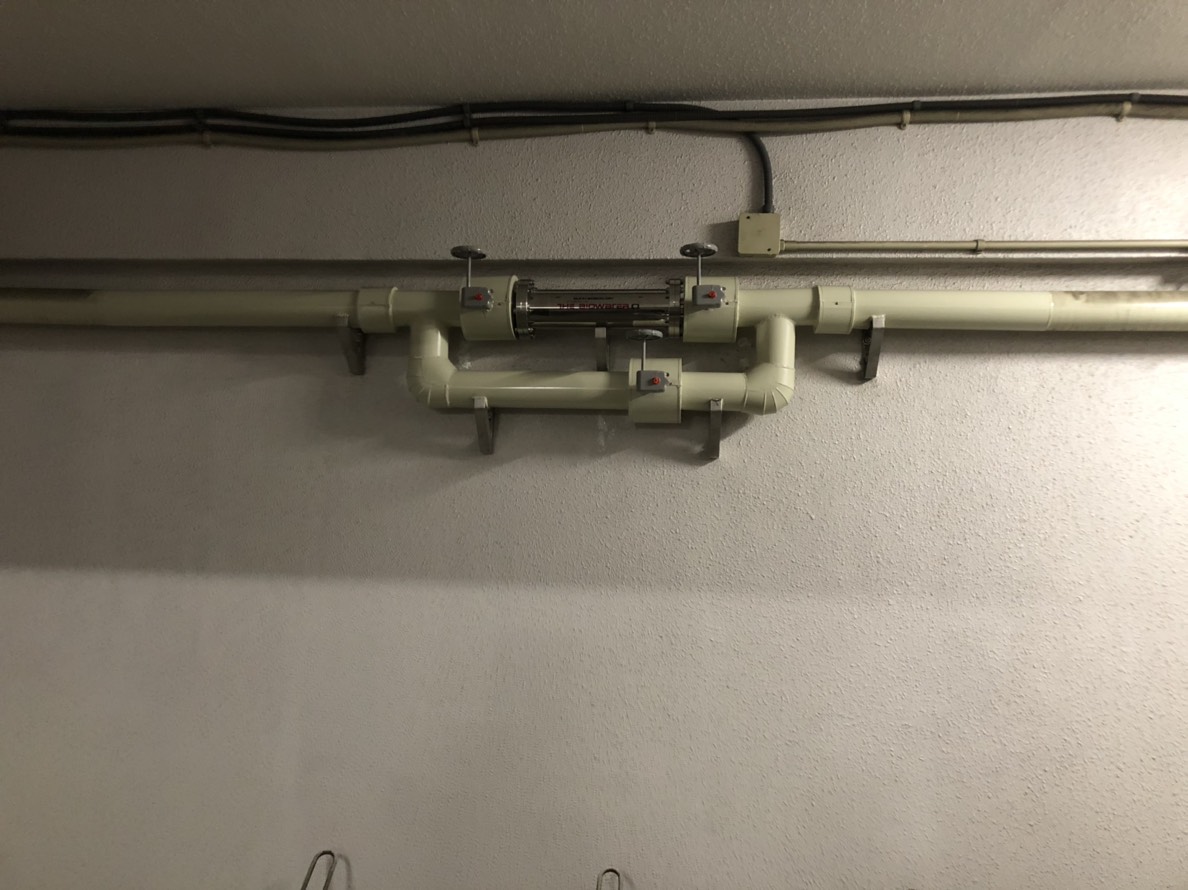

Model number of BWΩ (water reforming device) will be selected for the object facility based on the diameter of the water pipes, and quantity of BW plate will be decided based on the water capacity of water tanks.

BW equipment will be installed after water pipes are cut, and cut-off of water supply would take place depending on water supply system.

Installation example of BWΩ inserted between water pipes

(Installation of a bypass pipe is mandatory.)

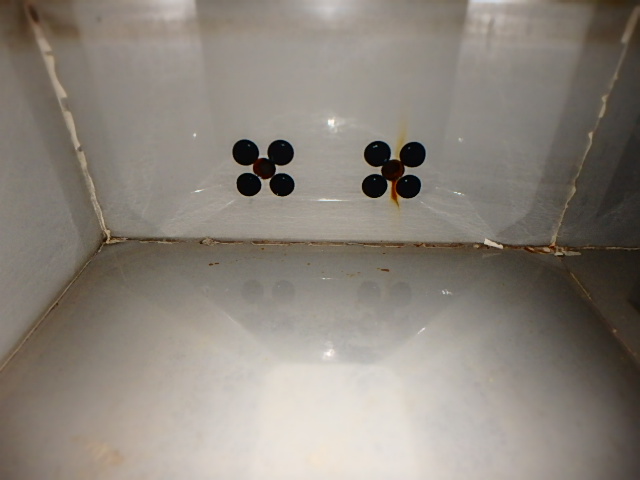

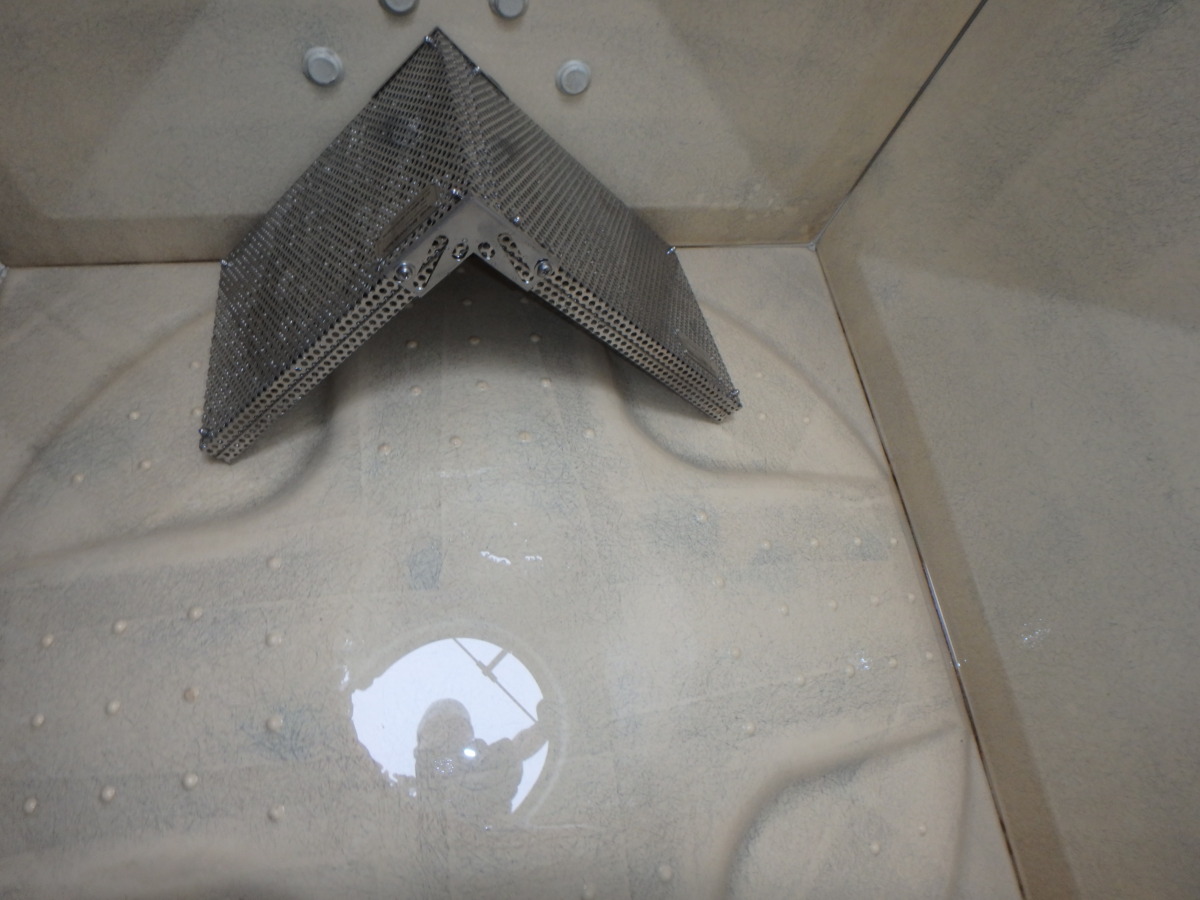

Installation examples of BW plate to be put in the water tanks(Various shapes are available such as box type, L shape, plate type)

STEP6Effects confirmation survey is available upon request

Summary-Feature and benefit of Magnetite Rust Method for water pipes

Magnetite Rust Method is an industrial technology for rust prevention based on Japanese traditional technology of water reformation. It is certified under NETIS (KT-1625-VR) (New Technology Information System of Ministry of Land, Infrastructure, Transportation and Tourism), and water reforming device that is our core technology is approved by Japan Water Works Association (Z-92).

We established measuring method to judge possibilities and effectiveness of BW water reforming device in advance of actual work, and such method is patented in Japan, USA, EU, Singapore and Malaysia. With our tests and investigations at individual premises before the work, our services of countermeasures for degradation of water supply pipes are safe, assured and reliable, and you can order with confidence.

Benefits of Magnetite Rust Method for water pipes

- Non-chemical, energy free and basically maintenance-free

- Short work period, low cost, effects last long until life of the facilities

- It can be applied regardless of degradation degree of water pipes and regardless of water leakage history

- Comfortable water environment is realized with the water reforming effects

- Method of “Sanpo Yoshi” (benefits for all three sides, good for everyone) and it serves reduction of water environmental burden.

Also, the method can be called as real industrial technology by satisfying rationality, operability and reproducibility, thanks to our own development of effects measuring device.

There are good chances where our method can be good solution to you if the building is older than 20 years. Please feel free to ask us for price quotation.

We offer best proposal to you considering the conditions of the premises.