What is scale ?

“Scale” which we talk about here, is elution of inorganic salts compound contained in water such as calcium, magnesium and silica, etc. If scale sticks on the facilities, it is difficult to remove. If scale is left alone, water pipes will be clogged and clogging by scale will be the cause of malfunctions of electronics equipment. Also, scale will bring energy loss and lowering production efficiency for the heat exchange system as scale will hinder heat exchange and cause heavier load. So, maintenance cost for periodical chemical input or cleaning becomes necessary.

Scale damage is apt to take place when industrial water used in factories is underground water of high hardness. Also, even when industrial water is not high in water hardness like general tap water, scale harm takes place when water element is concentrated due to water circulation by facilities having water circulation system.

Usually “Scale removing agent” such as acidity regulator or oxygen adsorber is used for countermeasures of scale damage, because scale growth can be inhibited with water having lower than ph 10. But, in recent years, the trend of scale countermeasures is not to use chemical agent because of 1.necessary running cost 2.contamination of global environment 3.health damage.

Examples of scale damage

- Clogging of water pipes, lowering water flow, clogging of spray-nozzle take place.

- Thermal conductivity is lowered when scale adheres to heat exchange facilities. (※)

- Scale may cause product quality problem.

- Cleaning solvent does not lather well.

※It is said that only 0.1mm thick scale is adhered in boiler, heat exchange efficiency lowers and fuel loss by about 1% will take place.

Scale countermeasures by T.K.K. Evolution

Reduction of electricity consumption for big electricity users is required in South-east Asian countries, and chemical application to cooling towers is prohibited in some countries from the viewpoint of prevention of global environmental pollution. Under such global trend, as countermeasure for scale damage, T.K.K. Evolution is recommending NCSC Method by BW water reforming device which does not use any chemical agent.

Examples of countermeasures for scale damage

Scale removal without cleaning by chemicals

Facility:Food manufacturing plant

BW installation place: Sakura city, Tochigi prefecure

We prepared test period to evaluate feasibility of the effects by BW water reforming device prior to installation work at this food manufacturing plant.

Water droplet was scattered by air around the surrounding facilities at the container washing line, and white scale was attached. Then, we tested to change to reformed water by installing BW water reforming device for the water cleaning system.

As a result, scale stuck to the facilities started to peel off gradually. We did not wash with reformed water by BW device, but this phenomenon took place only with air splashed water droplet. Based on this test results, BW plate is now used in the cooling tower of this plant.

Scale in the water pipe was removed 4 months after the BW installation

Building: Electronics manufacturing plant

Location:Atsugi city, Kanagawa pref.

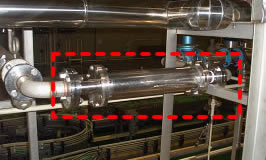

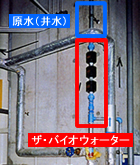

In July 2000, BW water reforming device (The Biowater) was installed at water supply pipe for boiler (well water).

We tested 2 months and 4 months after installation. Big scale removal effects were found at inside of water supply pipe of the boiler, inside pipe wall, screw portion of check up window.

Field test of scale prevention effects

Scale in the water supply pipe disappeared four months after installation of BW water reforming device (The Biowater).

- Date: July 15, 2000

- Building:Water supply pipe of the boiler at Electronics manufacturing plant. BW was installed at water supply pipe.

| 2 months after installation | Big scale removal effects were found at inside of water supply pipeof the boiler, inside pipe wall, and screw portion of check up window. |

| 4 months after installation | Scale adhesion was completely inhibited, and existing scale started to peel off. |

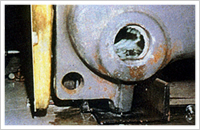

Observation from check up window of water pipe of the boilder

Scale is piled up inside of the pipe

Scale is almost removed

Scale adherence at low water cutoff device of the boiler

Scale is sticked

Most of scale is removed

Scale in cooling tower was removed 6 months after installation of BW. Red rust was also inhibited.

Building: Hotel

Installation location: Niigata city, Niigata prefecture

The hotel is located at five minute’s ride by taxi from JR Niigata station, and is popular for its good customer service and good facilities. But, scale was firmly stuck in fins of the cooling tower and it was a headache of maintenance service company. So, we installed BW water reforming device and BW plate in one of the two cooling towers, and monitored the progress.

Then, in 6 months after installation, we could see the big difference between the cooling towers with and without BW water reforming device.

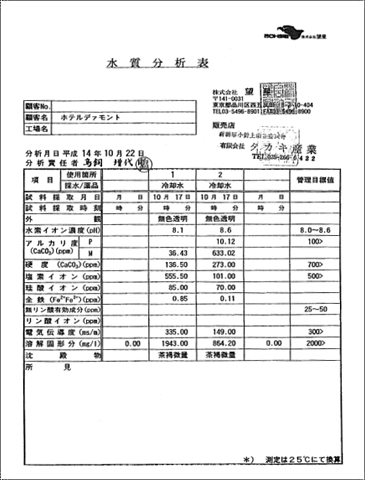

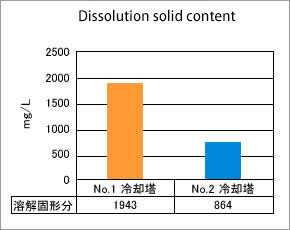

Test data of scale removal

Scale in cooling tower was removed remarkably and red rust was inhibited 6 months after the installation of “BW water reforming device” (The Biowater).

- Pick up of test water:April 15, 2002

- BW installation:October 17, 2002 (Measured on October 22, 2002)

- Location: Two cooling towers of a hotel

- Test agency: Bohsei Co., Ltd. (Shinagawa-ku, Tokyo)

Test method:

In one of the two exactly same cooling towers, one “BW water reforming device” (The Biowater) and two BW plates were installed.

For the test points of each cooling tower, (1)scale adherence conditions and (2)analyzation of cooling water were carried out.

Test results

Conditions of scale adherence

Scale is adhered in the cooling tower (No.1) without BW device.

Scale was peeling off very much in the cooling tower (No.2) where BW was installed (Refer to the photos)

Scale is drastically peeled off

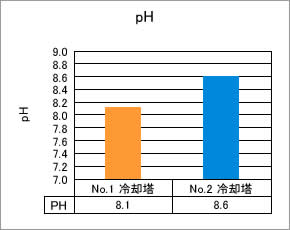

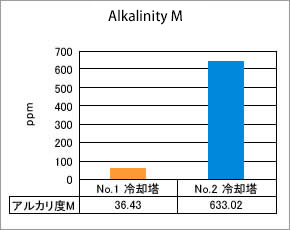

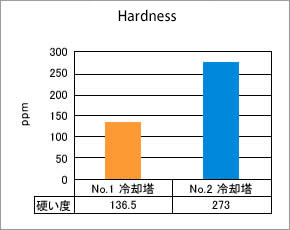

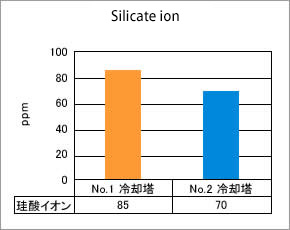

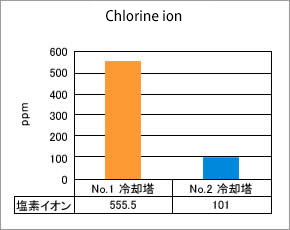

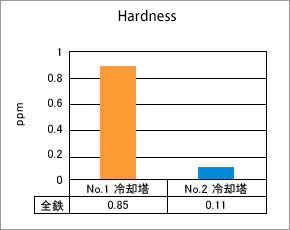

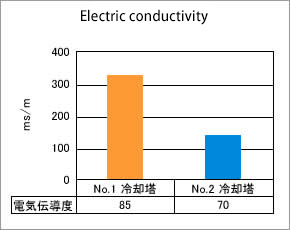

Water quality test of the cooling water

Value of total iron is drastically reduced from 0.85ppm to 0.11ppm.

It is because red rust generation was inhibited.

Hardness is increased from 136.5ppm to 273.0ppm.

It is because calcium carbonate is eluted in the water due to scale removal.

From the tests, it was verified that “BW water reforming device” (The Biowater) has excellent effects of anti-corrosion and scale removal.

Data graphs of water quality analysis

Scale made of calcareous water is removed and pipe cleaning becomes easy

Building: Hotel

Location: Ohshima-gun, Kagoshima prefecture

Okinoerabushima is called an island of flowers and limestone caves, and many tourists visit the beautiful island for blue sea and white sandy beach.

However, people living there have troubles of calcareous milky water. Water which can’t be drunk as it is, and concrete-like white lumps stuck in bathrooms and kitchen sinks. Many elderly people suffer from rheumatism with many years’ accumulation of calcium element of lime in their joints.

BW water reforming device (The Biowater) is installed in a town operated hotel there. People in charge of facility management were very happy because cleaning work became much easier after installation of BW. Furthermore, scale damage with water which hardness of about 300mg/L was gone by installing BW water reforming device (The Biowater). And, they had been spending much money for RO filter (Reverse Osmosis Membrane) but it became unnecessary to use RO filter any more.

The photo is Mr. Takekatsu Asado, Ex-deputy mayor of Chinacho town office in Okinoerabushima (right), and CEO of TKK Holdings.

Mr. Asado conveyed messages of Floral Hotel staff after installation of The Biowater device to us.

Mr. Asado himself installed The Biowater device in his home, and was impressed to witness the effects of BW. White limestones in the bathroom floor accumulated in many years began to peel off after BW installation.

Water collected from the hotel in 2007(Photo taken in 2009)

Both water (One is before installation of BW, and the other is after installation) looked transparent at first. As time went by , there were differences.

Tap water after BW water reforming device (The Biowater) was installed, continued to be transparent because calcium ion is surrounded by water element.

On the other hand, cloudy water not processed with BW is cloudy because calcium ion is combined with carbon dioxide gas and kept producing crystals of calcium carbonate. Here we can see the water quality differences.

Scale adhered to inside of a boiler and a heater starts to peel off in two weeks

Building: Food shop

Location: Shibuya ku, Tokyo

The lunch box delivery shop uses professional hyper steamer to heat up lunch boxes. White scale was adhered firmly between inside wall of the boiler and heater and heat transfer efficiency was decreased. Therefore, we installed 1/3 part of BW water reforming device in that place of the hyper steamer. (Due to limited space, we could not install whole device.) Scale started to peel off in two weeks and heat exchange efficiency was recovered.

Field test of scale removal

Scale in inside pipe of the boiler was removed with 1/3 part of BW water reforming device (The Biowater) in two weeks.

- Date: June 15, 1995

- Location: 1/3 size BW water reforming device (The Biowater) was installed in professional hyper steamer of food shop

Test results

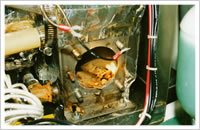

Inside wall of the boiler

Lots of scale adhered inside

Heater part of the boiler