Countermeasures for deterioration of water supply pipes

For the people who are seriously looking for good countermeasures for deterioration and degradation of water supply pipes (in the buildings)

Service life of buildings and water supply pipes, and proper countermeasures for water pipe deterioration.

Life of the building depends on deteriorations of building skeleton such as concrete and water supply pipes

Usually life of water supply pipes is considered to be 30 years,and it is said that countermeasures and repairs are necessary about 25 years after the completion of the buildings per the guidelines set by Ministry of Land, Infrastructure, Transportation and Tourism. Based on the guidelines,inhabitants of the apartments pay monthly management fee as a reserve fund for long term repair plan of the condominiums.

There are various types of water supply pipes in the buildings, and kinds of pipes are different depending on completion year of the buildings. Countermeasures for deteriorations will differ according to types of water pipes and uses of the buildings.

- Is water for daily use or for industrial use where the water pipes are used?

- Is the building with multiple floors or one floor house?

- How much considerations are necessary for the design?

Methods for best deterioration countermeasures vary depending upon above factors.

The cause of water pipe deterioration and major deterioration phenomena of today

The cause of water pipe deterioration is rusting of iron.Therefore, various kinds of water pipe were developed and made which are anti-corrosion and fire-proof.

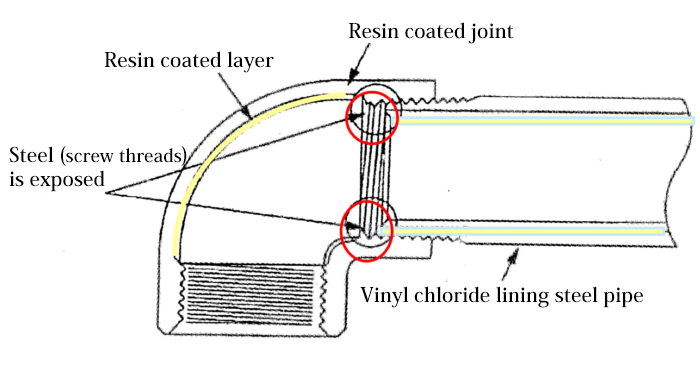

Internally coated lining steel pipe(VLGP pipe)

Around 1971, lining steel pipe(VLGPpipe) was developed, and the steelpipe has internal coating by vinyl film. By the introduction of the resin lining steel pipe, it was considered that red rust and deterioration problem of water supply pipes such as red water and water leakage was solved.However,as time passes, it was found that female screw threads at pipe end where the joint is connected touchwater and become deteriorated with corrosion.

Core built-in joint

To improve the problem at screw threads at the joint , core built-in joint was developed and marketed around 1998, but the quality was dependent on installation performance. Our investigation shows that 20 % of the case, deterioration by rust is found with poor installation.

Current solutions for deterioration of water supply pipes

- To replace whole water supply pipes with new ones

- Lining method repair: Remove all rust and remove vinyl chloride linings in the water pipes, and then newly apply resin coating in the water pipes.

Installation cost becomes very big in the case of above 1 (pipe replacement). In the case of 2,Lining method was very popular as pipe regeneration method for some time. However, it was pointed out that resin coated inside wall of the pipes cause elution of a carcinogenic substance called Bisphenol A and may cause health damage.

New solutions to replace conventional method have been searched for and the third method was classified. Academy of rust prevention calls it as “physical treatment method”. Typical methods for the third method are:

- Method using gnetic material

- Magnetite Rust Method which is developed by our company

The third method: Magnetite Rust Method

Magnetite Rust Methodis a repair method for old deteriorated water supply pipes (within the buildings), where thickness of pipe wall is reduced with red rust, and pipe wall thickness can be recovered by forming black rust in the pipe.

“Magnetite RustMethod®”(Oxide Coating Film Method) is certified as a new technology under NETIS (KT-160125-VR), of Ministry of Land, Infrastructure, Transportation and Tourism.

This method is an industrialization of the Japanese traditional technology to change water quality. By reforming water quality, red rust is changed to black rust, and the water pipe wall which thickness was reduced with red rust recovers to original thickness by formation of black rust.

Also, we developed measuring equipment with which how much changes took place in water quality. With the equipment,we can evaluate the possibilities of water reformation at the premises in advance of starting construction.(Patents obtained in Japan, USA, EC, Singapore and Malaysia for the equipment.)

Water reformation equipment (Trade mark “The Biowater”®” “BW” received JWWA certificate (Z-92) from Japan Water Works Association.

Proposal of countermeasures for deteriorated water pipes and water leakage prevention: For apartment owners

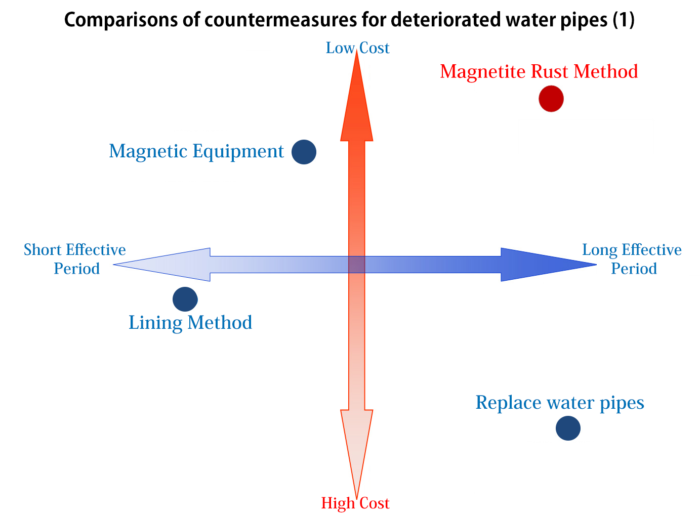

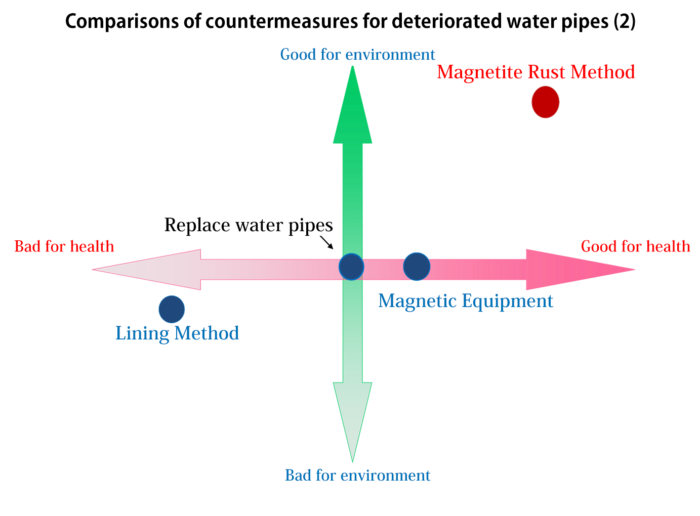

Comparison chart of major countermeasures for deterioration of water supply pipes

| Method | Main works | Approx. Cost | Work period | Effective period | Notes | Problem |

|---|---|---|---|---|---|---|

| Replacing water pipes with new ones | Remove old water pipes, and install new pipes. Or, install new pipes outside of building(exposed pipes) | $500,000~$1,000,000 (Per household: $10,000~$20,000) | 2~3months | About 20 years | Fundamental and quick solution, because of using new pipes | Cost is very expensive Long work period Need temporary dwellings Huge amount of disposals Appearance become bad when exposed pipes are installed |

| Lining method | Remove red rust in the pipes by polishing with sand blast. And apply resin coating in the pipes. | $150,000~$200,000 (Per household $3,000~$4,000) | 1~1.5months | About 10 years (warranty period) | Popular and widely applied method | Damages to the pipes. Health damage may occur with elution of environmental hormone from the coated resin. This can’t be applied for highly deteriorated pipes. 2nd work is not possible. Water leakage takes place in several years due to swelling of coated resin. |

| Magnetite Rust Method (Oxide Coating Film Method) | Install BW between water pipes. It will slow down speed of oxidation, and change red rust to black rust. Result is repairing of deteriorated portion of pipes. | $30,000~$40,000 (per household $600~$800) | 1/2~1day | Semi-permanent | Low cost & short work period. Applicable for water leakage pipes. Good effects to sewage pipes too. Improved cleaning, anti-oxidation and anti-bacteria power. Scale elimination. Reduction of burden on the water environment with BOD reduction. FS(feasibility study) is possible with effects measuring equipment. | Whenwater pipe deterioration is severe, time is needed to clean out red rust. If it is wanted to stop red water immediately, cleaning of water pipes is necessary. |

| Installation of Magnetic Equipment | Install magnetic system in the water pipes, and magnetize water, which will inhibit red rust accumulation in the water pipes. | $50,000~$100,000 (per household, $1,000~2,000) | 1/2~1day | Semi-permanent | Direction of magnetic field should be changed every several years. Equipment must be installed at every 50 meters length of water pipes. Additionalequipments are necessary when there is a water tank. No effects when water flow speed is slow. Effects can last only for several days. Effects are less for soft waters. |

As you can see from above chart, our own development “Magnetite Rust Method®” is long lasting in effects, cost effective and good for people and environment. Magnetite Rust Method is an effective countermeasure for deteriorated water pipes, without using new pipes and without using resin coating.

To apply this method, analysis of deterioration level of the water pipes is done first. As explained in earlier part, most suitable combination of countermeasures are different depending on application of water supply, kinds of the building and degradation level of water pipes, as well as the locations of water supply pipes system. For details, we will explain at “Process” of Magnetite Rust Method.

As our T.K.K. group companies have experiences of more than 150,000 construction & maintenance service numbers in water pipes, cleaning and inspections, we can make proposals for best solutions of water pipe deterioration as an expert in works and consultation. We are now explaining how to investigate and analyze deterioration of water supply pipes.

How we do deterioration analysis and investigate water supply pipes (in the buildings)

Standard degradation analysis of water supply pipes at our company is carried out as follows:

- Pick up sample water pipes. It is better to take out from multiple number of sample pipes from different areas of the building. We cut out from the joint area.

- Cut out the pipes vertically, and observe steel part and corroded part at inner boundary area of the joint. Record the area with microscope or 3D shape measuring device.

- Identify materials of the rust at the lowest layer of the joint area between steel and rust according to the customer’s request. (Test is carried out at public test agency using “fluorescent W-ray analysis”)

- Calculate the remaining life of the water pipes judging from the scoop out conditions of the deteriorated part.

(the more samples, the more accurate the calculation is.) - Use the vertically cut pipes as samples, and complete the report with data.

Make recommendation of the solution method with the investigation report and on-site report according to customer’s request. Application of “Magnetite Rust Method” only, or combination of “Magnetite Rust Method” and other method.

Click here for samples of the investigation report≫

Diagnosis of water pipes・Investigation charge

- Approximately $800 without material identification stated in 3 above, for one location of water pipes of 20mm~25mm diameter. (including the charge for pipe cut out work)

- Approximately $1,100 when material identification in above 3 is added.

- When Magnetite Rust Method is selected, it is possible to do feasibility investigation, only by collecting and evaluating waters of the site. (Charge : $400)

Analysis in case of other companies

They do some simple analysis, such as investigation of inside water pipes using fiberscope, etc. That can’t be accurate analysis. Just impressions of the current state of the pipes.

Menu of countermeasures for water supply pipe deterioration by T.K.K. Evolution

| Cleaning of water supply pipes | When red water is flowing, select best countermeasures from several methods, and clean up inside of water pipes. 【examples】”JAB cleaning method” water pipe cleaning system, Hydrogen peroxide solution treatment, etc. |

| Repair and replacement of water pipes | Diagnose conditions of water pipes, and apply following methods, according to deterioration level.

|

| Magnetite Rust Method (Installation of BW water reforming device) | Install BW device which reforms water and it is the fundamental solution against red rust. This method is highly effective for long period of water pipe maintenance, because it reduces existing red rust and prevents rusting in the future. Details of Magnetite Rust Method≫ |

We recommend “Magnetite Rust Method” as solution for deterioration of water pipes. Long lasting effects, cost efficient, and friendly for environment and human beings. Feel free to contact us for various questions.