What is red rust ?

Red rust is reddish brown oxide which is made when iron is touched with air and is oxidized. Rust which we see is usually red rust. Red rust is very gappy and very brittle. Red rust makes iron corroded and very brittle. It is called iron hydroxide or ferric hydroxide, and its chemical formula is Fe₂O₃ or FeO(OH).

On the other hand, black rust is a rust of good nature. Unlike red rust, it is dense film and prevents oxidation. There is traditional technology to make black rust intentionally on the metal like “black skin” and “black dyeing” and prevent red rust. It is called triiron tetroxide and its chemical formula is Fe₃O₄.

Differences of red rust and black rust

| Red rust(Fe₂O₃) | Black rust(Fe₃O₄) | |

| Shape | Muddy(brittle) ) | Crystalline(rigid) |

| Volume ratio | 10 | 1 |

| Color | Dark reddish-brown | Black |

| Water solubility | Red water flows out | No elution |

| Magnetism | No | Yes |

| Rust progress | Yes | No |

What is red water?

When old water pipes are deteriorated and red rust is made in the pipes, water becomes red and laundry is dyed red. This is red water. Red water is used to make red mud pigment paint. Iron bacteria lives in red water, and most of “general bacteria” counted by water quality inspection of tap water are iron bacteria.

Problems with red water

Red water does not exist in tap water in regular water supply pipes today. But, red water troubles are frequently seen in circular water pipes of factories. For the red water troubles, it can be solved when red rust floated in the water changes to black rust. Red water changes to transparent water when red rust settles down and changes to black rust.

For circulation water pipes of the cooling water at factories, low cost white gas pipes which don’t have internal coatings are used. It is because water quality does not matter for the application, unlike cleaning water used for manufacturing of semi-conductor wafers, in which case water quality will impact directly to the quality of product.

However, when red water is found, it is a sign that water pipe deterioration is progressing, and troubles like water leakage will take place sooner or later. For facility administrators, soonest countermeasures become necessary as asset management of production facilities.

Red rust and red water countermeasures by T.K.K. Evolution

We propose “Magnetite Rust Method” as countermeasures for red water and red rust. It changes red rust into black rust in the water pipes by installing BW water reformation equipment. We will introduce installation examples of “Magnetite Rust Method” which solves red rust corrosion with black rust.

Examples of red water countermeasure for water supply pipes

Head office/plant of NTTーAT Creative Co., Ltd.

Red water changed to transparent clean water in about 7 months after installation work.

A chemical manufacturing company (in Nagoya)

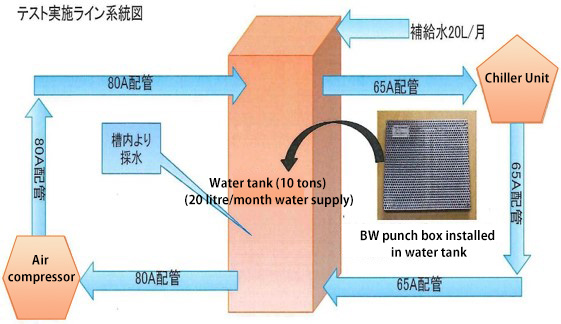

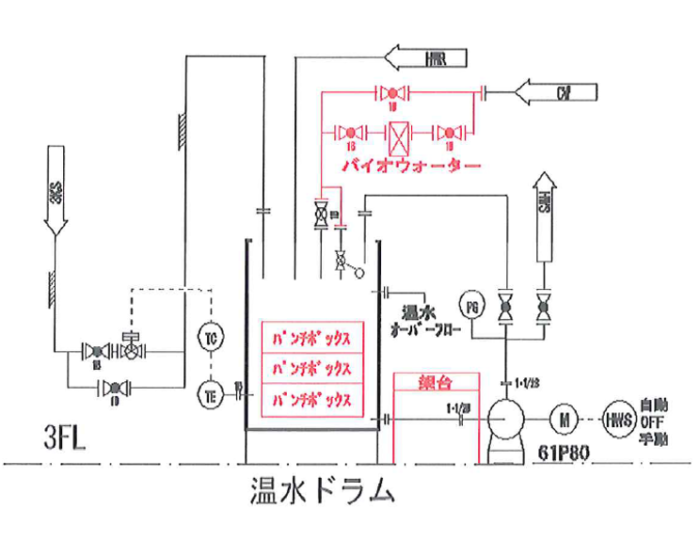

Facility of BW installation

(1 BW & 3 BW punch boxes installed)

Progress in 3 months (Feb. 18 vs. May 12)

Water quality test (3 months after installation of BW)

Water taken out from warm water drum/water quality test data

| Feb 18(before installation) Warn water drum | May 12(after installation) Warm water drum | |

|---|---|---|

| Iron | 1.1ml/l | Less than 0.05ml/l |

| Chromaticity | 20degree | 6.5degree |

| Turbidity | 4.1degree | 1.0degree |

Iron reduced to 1/22、Chromaticity reduced to 1/3、Turbidity reduced to 1/4.

Water taken out from warm water pipes/water quality test data

| Feb 18 (without BW) | May 12 (with BW) | |

|---|---|---|

| Iron | 79mg/l | 5.1mg/l |

| Chromaticity | 2000degree | 150degree |

| Turbidity | 700degree | 43degree |

Iron reduced to 1/15、Chromaticity reduced to 1/13、Turbidity reduced to 1/16.

Examples of countermeasures for red rust in water pipes

Shibaura Mechatronics Corporation

There are many factories of precision machinery manufacturing in Sakae-ku, Yokohama city. Among these factories, Shibaura Mechatronics is a comprehensive company who does development, manufacturing and services of manufacturing equipment for semi-conductor and electronics parts.

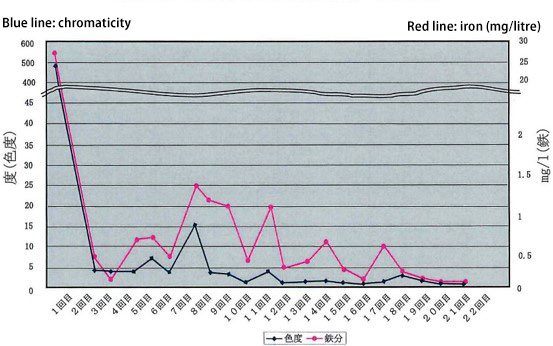

At this company, test of BW water reforming equipment was carried out to verify the effectiveness of deterioration prevention of water supply pipes.

Followings are test pieces. Rectangle shape is a thin plate of soft iron. Cylindrical shape is a GP tube joint which zinc plating was removed.

(Rectangle shaped soft iron plate contains less carbon than GP tube for tap water pipe and is not proper piece to confirm effectiveness of deterioration prevention of water pipes. But, since it is a flat panel, it is useful to check layer construction and corrosion status of rusts.)

We observed state of rust by placing two kinds of test piece in cushion tank (BW installed) in circular water, and in cushion tank (BW not installed) in cooling system for clean room.

Test pieces after 1 month of installation

Soft iron (observe state of corrosion by removing surface rust)

GP tube(observe real state of rust on water pipe)

These test pieces were checked 1 year later. But, symptom of corrosion was not found at all on the test piece with BW.

From the test results, it is found that shape and quality of formed rust become quite different between the one with BW water reforming device (The Biowater) and the one without BW device. From the test, it is verified that BW water reforming device has effects of deterioration prevention on water supply pipes.

Shikaoi town high school in Hokkaido

The school building of Shikaoi High School was 22 years old, and they were suffering with red water. An employee of facility service at the town office found BW water reforming device and installed in the building.

BW was installed in 2004, and three years later, old school building was destroyed and new building was constructed. And, some of old removed water pipes were sent to our company by town workers.

The old water pipes were covered with black rust which looked like coating work and protective calcium film covered the black rust. The area where corrosion was going to progress, was covered with thick scab-like black rust.

Details of field test

Date

Installation work :August 2004 (22 years old building)

Removal of sample : June 2007 (3 years 10 months after BW water reforming device was installed)

Location

Shikaoi Town High School , Kohto-gun, Hokkaido

Water supply pipes for whole building(lower than water receiving tank)

Sample pipe removed from the water pipe on the ceiling of 2nd floor (SGP50A)

Test results (sample pipe evaluation)

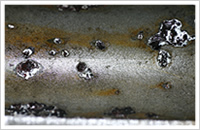

1:Sample tube (drawing 1) was cut horizontally, and inside tube (drawing 2) was checked. Then, red rust on the surface layer was taken off to investigate oxidative layer construction in the pipe wall. (soak into organic acid for 24 hours)

2:The result : It was confirmed that solid crystalline iron oxide (Magnetite Fe3O4)was formed on the corroded area inside the water pipe. (Figure 3)

As seen in the drawing 3, magnetite is formed and filled the holes in the pipe as if holes are repaired with fillings.

3:When layer construction is closely checked on the iron oxide, white film is spread over black rust. (Drawing 4). The white film is calcium and it is formed as if it is protecting the oxide film of black rust.

It is thought that the deterioration of sample tube was progressing with corrosion by red rust, before the work with magnetite rust method which was applied 3 years 10 months ago. The corroded part now is covered by black rust and it looks like holes are repaired by themselves with welded black rust plugs.

Furthermore, calcium film covers over black rust. With these double films pipes can prevent from corrosion and oxide film itself is also protected, which realizes ideal countermeasure for red rust problem.

From above situations, we can judge that satisfactory measures against deterioration of water pipes are accomplished and any future deterioration is prevented at this high school.

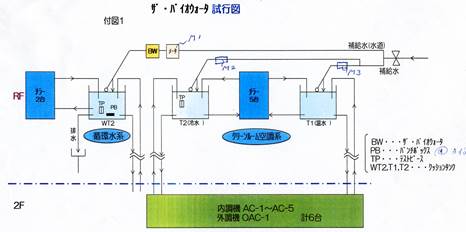

Hachioji Station Terminal Building

This is a case of “Hachioji Now”, a commercial facility with 10 stories and 1 basement floor at Hachioji Station in the suburbs of Tokyo. The facility accommodates restaurants, a fashionable super market, fashion and beauty shops. Safety of water is indispensable for the tenants.

BW water reforming devices (The Biowater) were installed at the building in 2006, and data was taken one year later.

It indicates that water was reformed to become safe water when we compare water quality before and after the installation of BW.

Values of “Sterization-related by-products” are drastically improved

| Inspection item & inspection date | September 14, 2005 Before BW installation | September 1, 2006 After BW installation | Variance |

|---|---|---|---|

| Chloroacetic acid (mg/l) | 0.002 | Less than 0.001 | 50%reduction |

| Chloroform (mg/l) | 0.016 | 0.003 | 81.2%reduction |

| Total trihalomethane (mg/l) | 0.017 | 0.006 | 65%reduction |

| Trichloroacetic acid (mg/l) | 0.02 | 0.009 | 55%reduction |

| Formaldehyde (mg/l) | 0.005 | 0.003 | 40%reduction |

Also, big effects for red rust prevention were confirmed.

Black rust was formed on the pipe wall below the location of BW water reforming device, and it prevents corrosion of pipe by red rust.

Kotesashi Heights in Saitama prefecture

There are more than 20 buildings of Kotesashi Heights near from Kotesashi Station of Seibu Ikebukuro line. BW water reforming devices are installed in “J” building, one of the condominiums.

Before BW water reforming devices (The Biowater) were installed, U.S.A. made magnetic equipment was installed at J building as countermeasure for red rust. Soon after the magnetic equipment was installed, red water was caused and inhabitants complained that the equipment was not working. Home management association of J building decided to remove the magnetic equipment, and after one year’s testing, they decided to select and install BW water reforming device (The Biowater).

They tested for five years (six years including one year’s test period) for the effects against red rust by BW water reforming device.

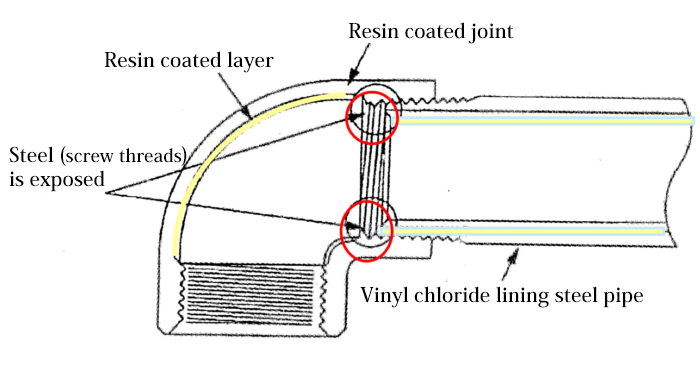

Water supply pipes at Kotesashi Heights were VLGP steel tubes which have resin coated joint inside of the wall.

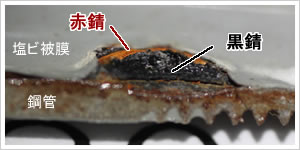

Screw portion of the joint is steel exposed like the drawing, due to the construction of VLGP steel tube.

Screw portion is exposed and contact with water. And corrosion progresses by red rust.

Also, in the area which is covered by vinyl chloride lining, water penetrates between the lining and base iron at the edge of the pipe, and iron corrosion begins from there and holes will be created in time.

With VLGP tubes, usually deterioration by red rust takes place at the two points, (1) screw occlusion part and (2) area between vinyl chloride film and base steel. But, when BW water reforming devices (The Biowater) were installed at this building, red rust was changed to black rust and deterioration of the water tube was stopped.

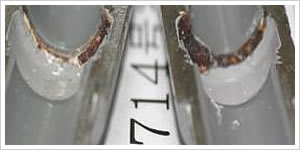

(Photo shot at Room No. 714 in August 2010)

Iron always become rusted when touched with water. However, when it is black rust instead of red rust, iron won’t be rusted and be protected by oxidative film of black rust.

There is “Cor-Ten steel”. Its surface is covered by dense rust and inside won’t be corroded. And, it is highly durable steel and is used for making bridges and railway trains.

Magnetite Rust Method using BW water reforming device (The Biowater), uses the same anti-corrosion method as “Cor-Ten steel”, and protect water pipes from red rust deterioration.

We recommend to use “Magnetite Rust Method” for countermeasures against red rust and red water.

It has long lasting effects and is cost-effective, friendly to environment and human beings.

Feel free to send inquiries when you have questions or concerns.