What is NCSC Method

“NCSC” of NCSC Method is abbreviation of Non Chemical Scale Control. It is a method to control adherence of scale without using chemicals.

By using BW water reforming device, the method is to remove scale or to prevent adherence of scale such as calcium carbonate (CaCO₃)and silicon dioxide (SiO₂) which hinder heat exchange. The method brings effects of reducing electricity consumption and usage of chemicals. (Patent No. 6703660)

NCSC Method

removes scale and prevent scale adherence by reforming water and brings reduction of electricity power consumption

Mechanism of scale removal and prevention of scale adherence

Against calcium carbonate (CaCO₃)

In case of regular water

Generally, in water supply facility, water is sent by pressuring water with a pump. Therefore, in the highly pressured water lots of gas are dissolved. When water faucet is open and water becomes under normal pressure, dissolved gas is vaporized and lots of bubbles are generated.

Under such conditions, carbon dioxide in the water is combined with calcium ion and crystallization of calcium carbonate (CaCO₃)advances.

In case of BW reformed water

In reformed water, gas dissolved in the water is not vaporized and clathrated (hydration) in succession of water molecule, and well-matched water molecule keeps stable state.

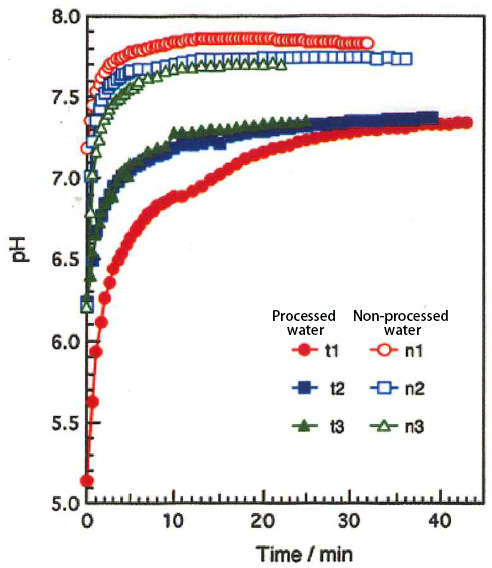

It can be confirmed as “alkali shift phenomenon found in regular water after water faucet opening is inhibited. (Drawing below :pH value shift in time, with processed and unprocessed water)

For processed water, calcium carbonate (CaCO₃) sticked as scale reacts with carbon dioxide(CO₂)clathrated in the water, and becomes water soluble calcium bicarbonate. (Ca(HCO₃)²) Then, adhered scale is easily peeled off.

CaCO₃ + CO₂ → Ca(HCO₃)²

(measured by adding 0.1MKCL supporting electrolyte)

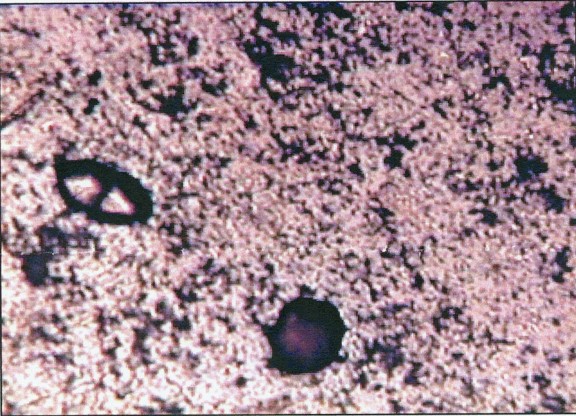

In reformed water, scale is deposited as calcite crystal (granular crystal). Calcite crystal is hard to adhere as scale, and is easily wiped off if adhered.

On the other hand, in regular water, aragonite crystal (needle-shaped crystal) is easy to adhere firmly as scale and it inhibit heat transfer because it contains lots of air layers, having 10 times of volume compared to calcite crystal.

Against Silicon dioxide (Silica=SiO2)

in case of regular water

Silica (silicon dioxide) forms gel-like film, and is gradually piled up and forms solid scale and adheres.

in case of BW reformed water

In reformed water, Silica is surrounded by water molecule and formation of gel-like film is prevented. Therefore, it is not likely to happen accumulation of silica nor scale adherence.

Example at a precision injection molding plant

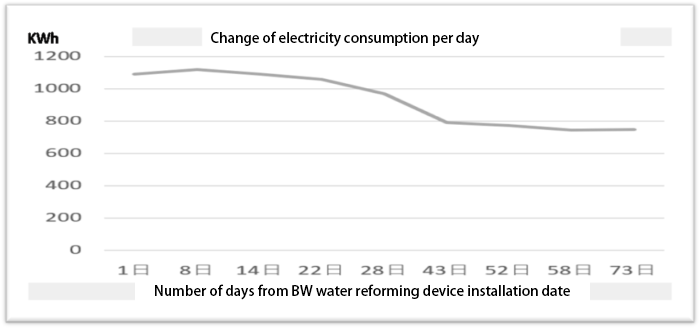

Saving energy effect

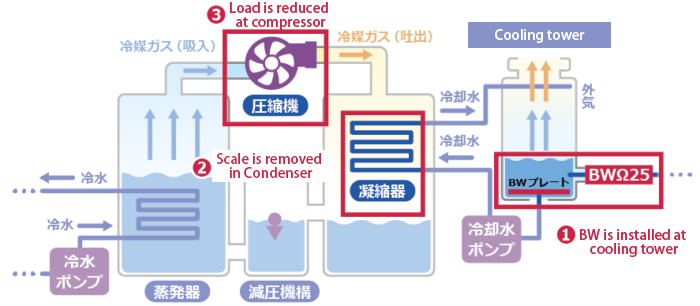

One BW plate was put in cooling tower, and one BWΩ25 was put in water supply pipe. Scale in cooling water supply pipe was removed, and heat transfer efficiency was improved.And, load of compressor (Refrigeration compressor) was reduced, resulting in 30 % reduction of electricity consumption.

Lengthening of filter replacement cycle

It is decided to replace filter installed in cooling water pipes for production facility when water pressure of passing cooling water reaches 5.0kg/cm2.

For regular water: Water pressure reaches 5.0kg/cm2 in one week.

For reformed water: Water pressure at the time of filter replacement was 1kg/cm2, and it became only 3.4kg/cm2 after 3 weeks.

Filter replacement cycle was extended drastically from one week to more than one month.

Investigation method about feasibility study of NCSC method

It is possible to evaluate feasibility of NCSC Method in your case by doing test in advance.

Test method about applicability of NCSC Method: Evaporation residue test

To reduce uncertainty of “knowing effectiveness after actual execution”, we do testing of feasibility study (test to assess applicability). Procedure is as follows

- Evaluate test data of water used in the facilities of planned implementation. If necessary, we do water quality test ourselves.

- Submit 4 litre of sample water from the facilities planned for installation to our lab.

- Make two kinds of samples. Half of the sample water is processed by BW equipment, and the other half not processed by BW equipment.

- Vaporize sample waters in thermoregulator, and increase concentration of scale component in the water, and educe scale component on the metal plates.

- Compare crystals on the plates in water with and without BW equipment process by microscope.

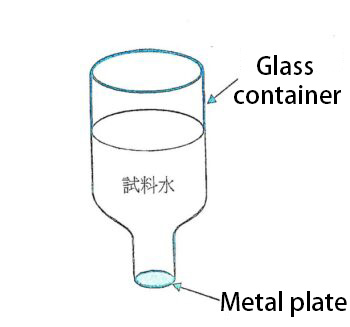

Procedure of evaporation residue test.

- Put in processed water and non-processed water in glass container. Top of the container is open, and bottom is sealed y iron plate with zinc plating removed and Viton rubber packing.

- Heat up the container by dipping into 98℃ water, and condense dissolved substance to 10 times in concentration rate, and educe the substance.

- Dispose of condensed water and dry the metal plates by air blower.

- Observe the evaporation residue educed on the iron plate by microscope.

Crystallization test at AIST(CaCO₃)

National Institute of Advanced Industrial Science and Technology

Summary of NCSC method

- Scale removal and scale prevention for facilities and water supply pipes without using chemicals and electricity.

- With improved heat exchange efficiency, electricity power consumption for compressor of refrigerating machine is reduced by 30 %.

- Filter replacing cycle can be extended drastically.

Other examples of installation of NCSC method

Factories

- 「Natural scale removal without chemical washing」a food manufacturing plant (Sakura city, Tochigi prefecture)

- 「Scale in water pipes was removed after 4 months of BW installation」an electronics manufacturing plant (Atsugi city, Kanagawa prefecture)

Hotels

- Scale adherence by calcic water was removed and cleaning of pipes became easy (Ohshima gun, Kagoshima prefecture)

- Scale in cooling tower was drastically reduced 6 months after BW installation, and red rust was inhibited(Niigata city, Niigata prefecture)